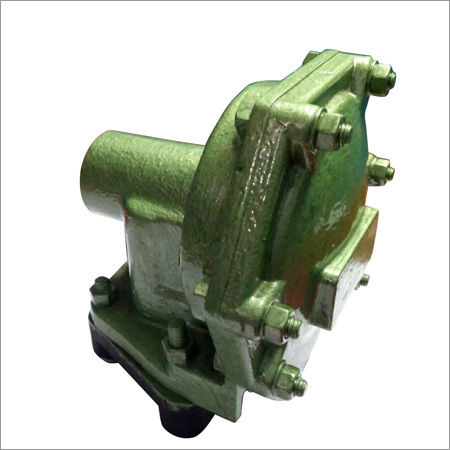

Safety Valve Type J-1

Safety Valve Type J-1 Specification

- Type

- Valve

- Pressure

- High Pressure kgf/cm2

- Media

- Air

Safety Valve Type J-1 Trade Information

- Minimum Order Quantity

- 50 Pieces

- FOB Port

- Kolkata

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Wooden Box

- Main Domestic Market

- All India

- Certifications

- ISO, NSIC

About Safety Valve Type J-1

A particular kind of safety valve frequently employed in numerous industrial applications to guard pressure containers or systems from overpressure is the Safety Valve Type J-1. Safety valves are essential parts that automatically release excess pressure in a system and guard against catastrophic failures.

Due to the fact that there are numerous standards and requirements for safety valves, the Type J-1 Safety Valve is probably a designation unique to a single manufacturer or standard. I can, however, give a general review of safety valves and how they work.

A safety valve typically consists of a valve body, a spring-loaded disc or nozzle, and a mechanism that opens when the preset pressure is exceeded and releases excess pressure. Under typical operating circumstances, the valve will remain closed thanks to the spring mechanism. The valve opens when the pressure rises above a specified set point because more force is being applied to the spring than to close the valve.

The excess pressure can be evacuated to a safe area, such as the atmosphere or a containment system, when the safety valve opens. This guards against hazardous explosions or structural collapses by preventing the pressure vessel or system from rising to risky levels.

Any safety valve, including the Type J-1, is chosen based on a number of variables, including the application, system pressure, temperature, flow rate, and any applicable rules or laws. To guarantee their dependable operation and compliance with safety criteria, it is essential to make sure that safety valves are appropriately sized, fitted, and maintained.

Please provide more context if you have specific queries or need more in-depth information regarding safety valves or a particular application. I'll be happy to help you further.

Features:

- Rugged construction

- Easy to mount

- Rust proof

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

More Products in MS Valve Category

UIC Type Angle Cock

Minimum Order Quantity : 50

Pressure : Other, Max 10 Bar

Type : UIC Type Angle Cock

Media : Other, Air (Pneumatic)

Power : Manual

SA- 9 Independent Brake Valve

Minimum Order Quantity : 50 Pieces

Pressure : High Pressure kgf/cm2

Type : Valve

Media : Air

Power : Pneumatic

C2W Relay Valve

Minimum Order Quantity : 50 Pieces

Pressure : High Pressure kgf/cm2

Type : Valve

Media : Air

Automatic Drain Valve

Minimum Order Quantity : 50 Pieces

Pressure : High Pressure kgf/cm2

Type : Valve

Media : Air